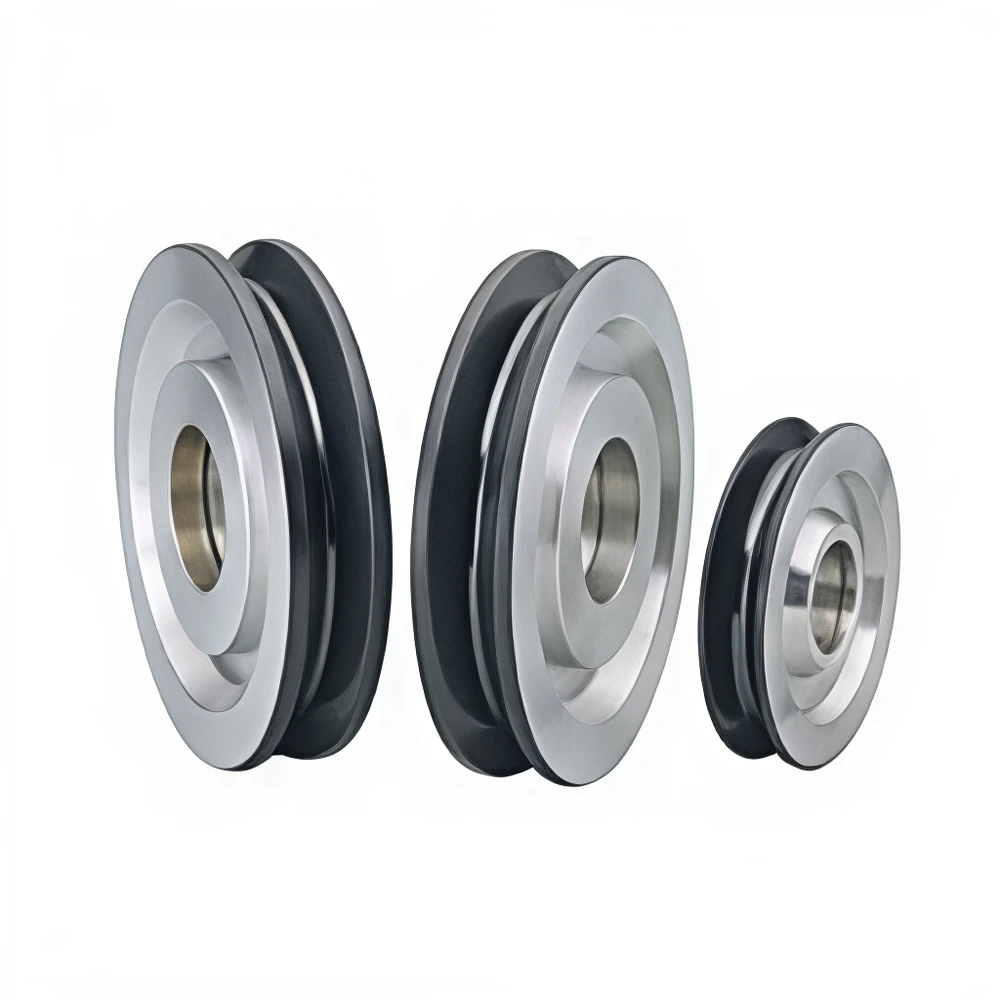

Chromiun oxide coating pulley

Product Introduction

Chromiun oxide coating pulley, with their high hardness, wear resistance, corrosion resistance, and low friction coefficient of surface ceramic coatings, are used to guide copper wire, aluminum wire, alloy wire, and other wires in processes such as drawing and twisting. Ceramic coating can reduce the friction damage between wire and guide wheel, ensure the surface smoothness of wire, and resist the wear caused by long-term friction of wire, suitable for high-precision wire processing needs.

Compared to tungsten carbide coatings, ceramic coatings are more suitable for low impact scenarios that require high surface smoothness, such as guiding precision wires such as chemical fibers and electronic leads, or environments that come into contact with corrosive media such as textile additives and weak acid solutions. Its low friction coefficient can reduce wire scratches, and its high corrosion resistance is suitable for complex chemical environments

product display