Tungsten Carbide coating Valve

Product Introduction

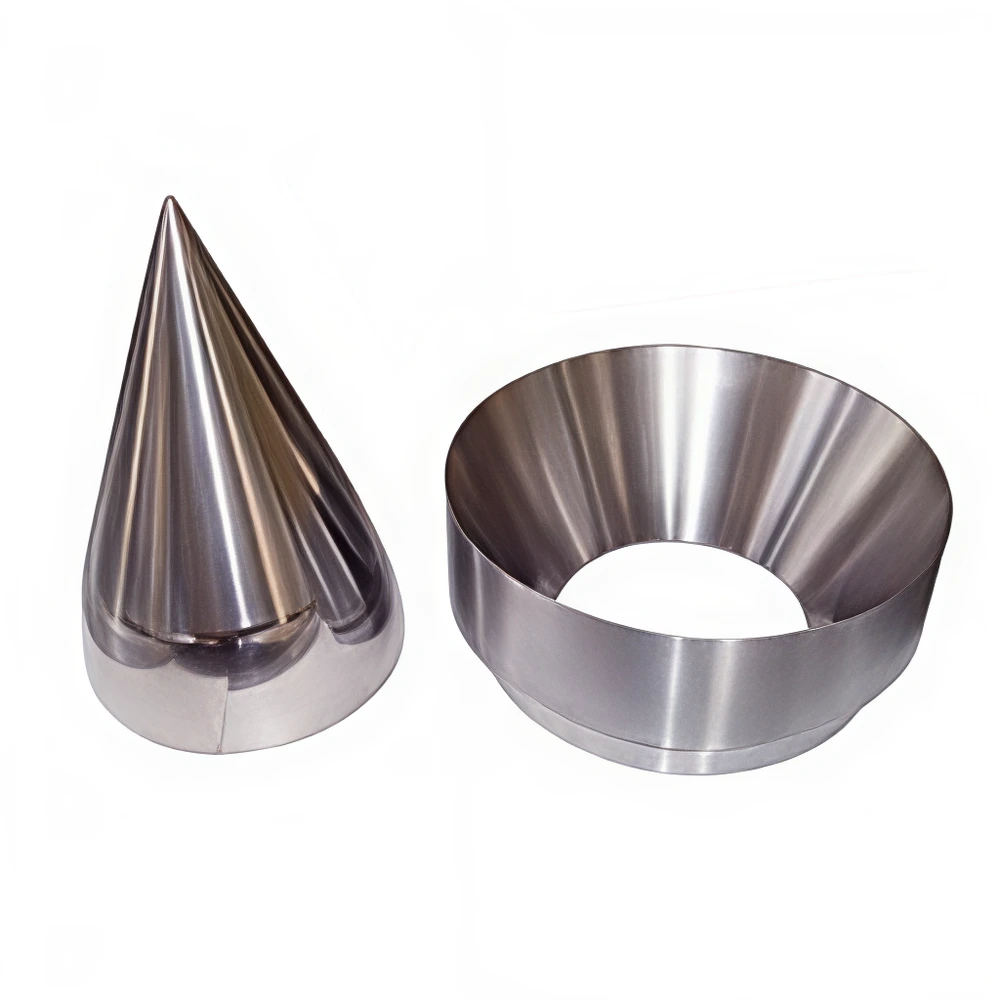

The valve of hydroelectric power generation is a key component in the control system of hydroelectric power plants, mainly used to regulate the flow rate and pressure of water entering the turbine. It achieves precise coordination between the needle shaped valve core and valve seat to open, close or fine tune the water flow, thereby stabilizing the turbine speed and ensuring the safe and efficient operation of the power generation system.

Valves need to work in environments where high-pressure water flows for a long time and the medium (which may contain impurities such as sediment) wears away, requiring extremely high sealing, wear resistance, and structural stability. Tungsten carbide coating enhances the wear resistance, sealing, and impact resistance of needle valves, enabling them to better adapt to the harsh working conditions of hydropower stations and reduce maintenance frequency and costs.