Specializing in industrial machinery components, CJ offers professional surface coating solutions

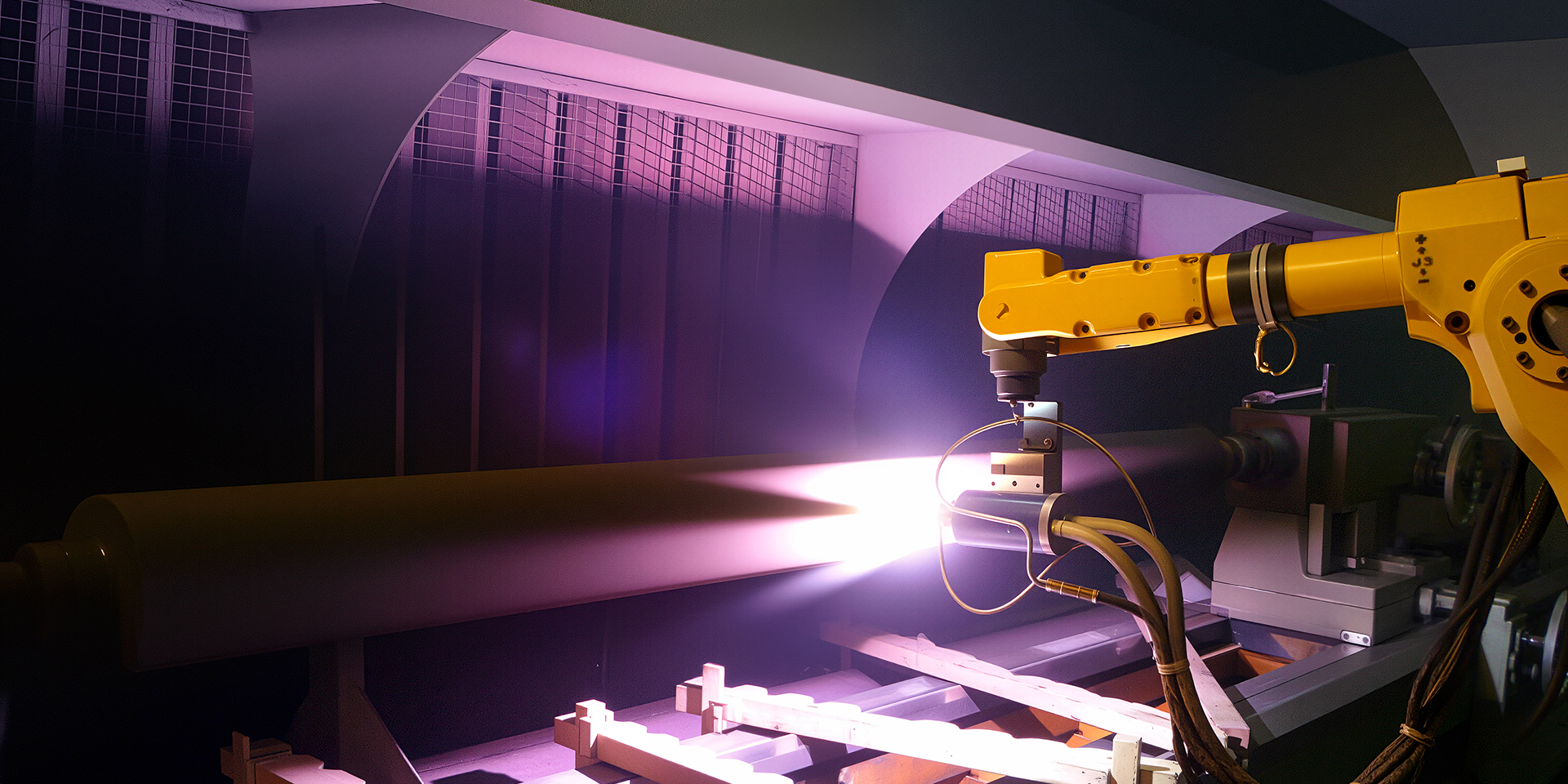

Using advanced spray welding equipment from Europe and America, as a professional thermal spraying company is dedicated to providing various high-performance surface spray welding coatings for mechanical parts across different industrial application scenarios. We meet diverse application needs such as wear resistance, high-temperature impact resistance, acid and alkali resistance, chemical corrosion resistance, anti-sticking, oxidation resistance, and insulation.

Chuan Yi Machinery - 40 Years of Expert Custom Thermal Spray Coating solution

no data

Discover our products

With 40 years of expertise, our thermal spraying company in China can customize mechanical parts for customers based on their provided drawings and coating-material requirements.

no data

Professional surface coating solutions

Provide us your inquiry spare part drawing with detailed information such as size, material and surface treatment requirment, we will produce corresponding products according to the drawing requirements.We could also meet the customer's needs for changing product materials, such as changing the sprayed product to a fully sintered zirconia product. Based on the original drawings provided by the customer, we could design new drawings according to the requirements for the customer to customize the new product.

no data

About Chuan Yi Machinery

CY is a leading thermal spray coating company established in Taiwan in 1985, under the umbrella of the Creativity Group. Specializing in industrial machinery components, CJ offers professional surface coating solutions such as spray welding and surface treatment to enhance the durability and performance of spare parts for wire drawing machines. With a focus on increasing production efficiency, CJ strives to provide high-quality and innovative solutions for their customers in the manufacturing industry.

Learn more about us

CY believes it is our mission to create the best solution for our customer, from R&D to full scale manufacturing. To gain a deeper understanding of our company, please explore our latest news.

Amid the roar of factory floors, within the steel and iron of urban infrastructure, and even on the delicate components of medical devices, thermal spray technology is playing a crucial role as an invisible guardian. This process, which transforms materials into specialized coatings, has long transcended the confines of the laboratory and has become a practical solution to addressing pain points across industries.

2025

08

19

In the medical field, the application of thermal spraying technology embodies its unique combination of precision and user-friendliness. The surface treatment of artificial joints demands extremely high biocompatibility, requiring them to be compatible with human tissue while also possessing sufficient wear resistance to withstand daily activities. Hydroxyapatite coatings created using thermal spraying technology, with a composition similar to the inorganic components of human bone, promote the growth of bone cells on the surface of artificial joints, achieving "osseointegration." This not only strengthens the implant but also reduces the impact of wear debris on the body, significantly improving patients' quality of life. From large-scale equipment in heavy industry to medical devices critical to life and health, thermal spray technology, with its unique "coating magic," solves practical problems in diverse scenarios. As the technology continues to advance, we believe it will create unexpected application value in even more fields, continuously bringing convenience and breakthroughs to our daily lives.

2025

08

19

no data

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Quick Links

Contact Us

Contact person: Eric Cheng

Tel: +86 13862630011

E-mail: eric.cheng@cy-cyf.com

Add: No.120,ChunJiang Rd., LuJia Town, KunShan City, JiangSu province, China

Contact us

Leave your inquiry, we will provide you with quality products and services!

Customer service